Pneumatic marking machines, which can mark on products, are becoming more and more important. They mark products with exclusive logos and strictly prevent "copycats". At the same time, they can also play a promotional role for products. When there are problems, they can also do Permanent traceability to the product.

Therefore, the use of pneumatic marking machines in industrial marking is very common, especially for the marking of cart frame numbers, motorcycle engine number marking, liquefied gas cylinder marking, flange marking, metal nameplate marking, etc.

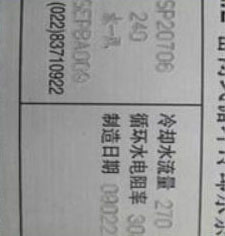

Case cover marking sample

Case cover marking sample

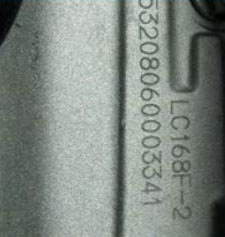

Engine marking samples

CHUKE marking machine- As a professional manufacturer of pneumatic marking machines for more than 20 years, we are here to introduce some possible faults that you may encounter.

1. The marking is not clear and the effect is poor

The unclear typing of the pneumatic marking machine is generally caused by the low temperature of the machine. So we can preheat the machine for 15 minutes before marking, and then start coding. If there is an urgent need for equipment for marking work, the temperature can be adjusted to a high temperature state first, and then the marking work can be carried out when the temperature rises to a stable level.

2. Pneumatic marking machine cannot work normally

There are usually several factors that cause this kind of failure: 1. Check whether each line is connected correctly, and see if the switch is turned on; 2. Check whether the intake pipe and air pipe are connected correctly; 3. Check whether the fuse is damaged and whether the power supply system is normal. ;4. Before starting the equipment, it is best to check the parts carefully to prevent connection problems caused by loose parts due to long-term use. Note: During the marking process, it is necessary to strictly follow the steps in the manual for coding, and do not arbitrarily change the operating procedures.

3. Pneumatic marking machine cannot print fonts

This failure may be caused by the lack of the font in the font library. We can check the status of the font library and import the required font into it.

4. The steel print made by the pneumatic marking machine is deformed or shifted

There are usually several points to cause this kind of failure: 1. It is possible that our needle is not tightened or the needle is loose due to long-term use. In this case, we only need to tighten the needle with a wrench; 2. The content of the mark exceeds the established 3. The service life of the pneumatic marking machine is too long, resulting in a larger gap between the guide rails, and the guide rails need to be replaced.

Are these tips helpful for your work? Just contact us to know more about it.

Post time: Jul-22-2022