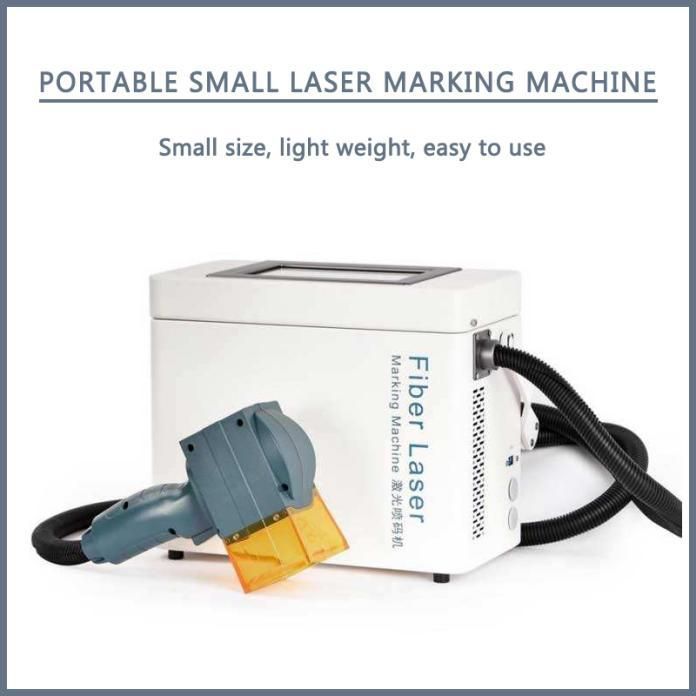

In a significant development for the industrial manufacturing sector, a renowned manufacturer has unveiled a state-of-the-art mini laser marking machine designed specifically for metal materials. This cutting-edge device is set to revolutionize metal marking processes, offering enhanced precision, efficiency, and versatility.

The compact size of the mini laser marking machine allows for easy integration into existing production lines, saving valuable factory space. Its advanced technology combines high-power laser beams with advanced optics, enabling users to achieve superior marking quality with exceptional accuracy.

One of the standout features of the mini laser marking machine is its compatibility with various types of metals, including steel, aluminum, brass, and titanium. Thanks to its powerful laser capabilities, it can mark intricate designs, serial numbers, logos, and even barcodes on these materials with remarkable clarity and durability. The machine also boasts a reliable cooling system to ensure continuous operation even during demanding production runs.

Furthermore, the mini laser marking machine offers extreme flexibility, allowing manufacturers to adjust the marking parameters according to their specific requirements. This adaptability enables deep engraving, surface marking, and even annealing without compromising on efficiency or quality.

The introduction of this advanced laser marking machine has garnered significant attention within the manufacturing industry. Manufacturers across various sectors, including automotive, aerospace, and electronics, are eager to take advantage of its cutting-edge technology to streamline production processes and improve product identification and traceability.

Several key benefits make the mini laser marking machine stand out from traditional marking methods. Firstly, its non-contact marking process eliminates the risk of damage or deformation of metal surfaces, ensuring a flawless finish. Secondly, the high-speed marking capability significantly enhances production efficiency, reducing downtime and increasing output. Lastly, the machine’s compatibility with a wide range of metal materials allows for seamless integration into diverse manufacturing operations.

Industry experts have hailed the introduction of this mini laser marking machine as a pivotal moment in metal marking technology. Its innovative features, combined with its affordability and accessibility, position it as a game-changer for manufacturers seeking to elevate the quality and value of their products.

In conclusion, the launch of the mini laser marking machine for metal by a leading manufacturer heralds a new era in industrial manufacturing. Combining precision, versatility, and efficiency, this cutting-edge device is poised to transform metal marking processes across various sectors, empowering manufacturers to optimize production and achieve exceptional results.

Post time: Nov-27-2023