Laser marking is a non-contact processing, which can be marked on any special-shaped surface, and the work piece will not deform or generate stress. It is suitable for various materials such as metal, plastic, glass, ceramics, wood, and leather; it can mark barcodes, numbers, and characters. , patterns, etc.; clear, permanent, beautiful, and effective anti-counterfeiting. The marking line width of laser marking can be less than 12pm, and the depth of the line can be less than 10pm, which can mark the surface of small parts of millimeter level. Low operating cost, no pollution, etc., can significantly improve the grade of the marked product. Laser marking method Laser marking method can be divided into dot matrix laser marking method, mask laser marking method and galvanometer laser marking method. There are three marking methods.

Here we focus on introducing our galvanometer laser marking machine.

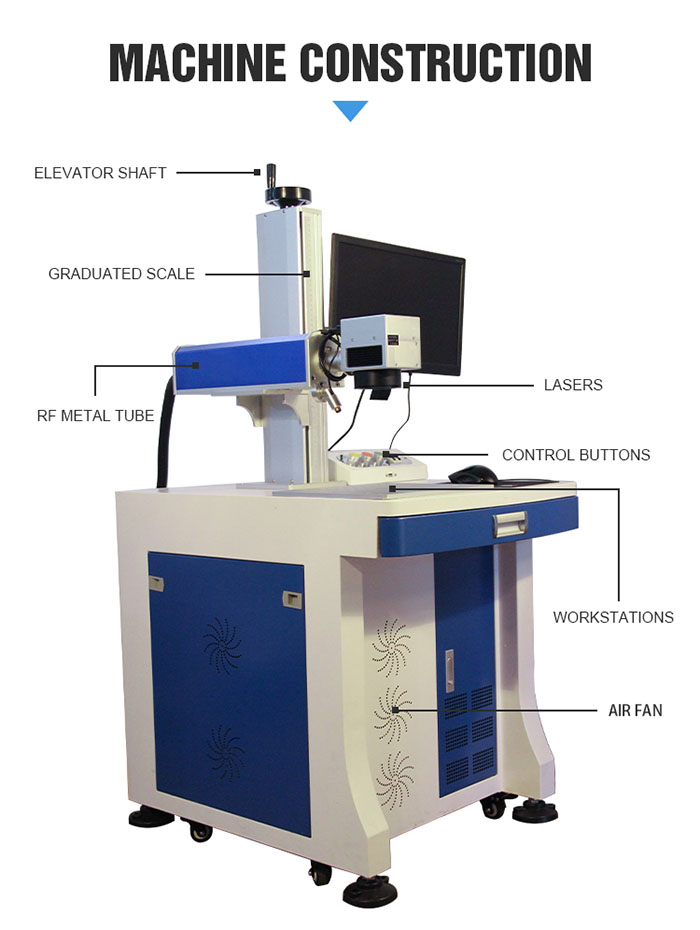

The conventional equipment mainly includes: rack, laser, galvanometer, motion axis, workbench, computer power supply, control system, cooling device, etc.

Among the various components, different components also correspond to different functional positioning of the laser.

Among them, the laser is the core component of the equipment. Different types of lasers are suitable for different processing materials. For example, UV lasers are suitable for plastic marking, such as charging header text marking; CO2 lasers are suitable for wood marking, while fiber lasers are more For marking metal materials.

In addition to the types of lasers, lasers are also divided into pumped YAG, optical fiber, video, glass tube, etc. according to different light output methods.

The output mode of the laser also corresponds to different equipment types, such as continuous laser processing equipment, single pulse processing equipment, and repetitive pulse processing equipment. In terms of processing methods, there are also different processing methods such as large-format processing, array processing, and splicing processing.

The current mainstream of the cooling system is air cooling and water cooling, among which water cooling is more stable, and the specific situation depends on the power of the equipment.

The control system part is mainly the computer and the marking control system, of which the computer is the main part of the electronic system. The marking control system is produced by specialized industrial manufacturers and is connected to the marking equipment. Generally, it will be equipped with a corresponding software system. The work only needs to be operated on the computer.

So how to choose the suitable one for your work/product? Please pay attention to following steps.

1. Recognised the material and choose the right type Dynamic CO2 laser marking machines can be used on non-metallic materials, and optical fiber laser marking machines normally used on metal and some non-metallic materials.

2. Good marking quality depends on good laser source.

3. High-speed galvanometer is 30% higher than traditional production efficiency.

4. Good laser punch must be simple to operate, high in efficiency, low in labor costs.

5. After-sales in an important factor to choose this industrial marking machine.

Choose the CHUKE laser marking machine to achieve your excellent work.

Post time: Jul-22-2022