Laser Engraving, Cleaning, Welding and Marking Machines

Get a quote

Products

Continuous/ Pulsed Laser Cleaning Machine For Metal

Product Description

Compared with traditional cleaning machine, CHUKE laser cleaning machine is more green, energy-saving and efficient industrial cleaner for rusts, paints, and coating removal. Its with wider scan area to improve the clean accuracy and efficiency.

CHUKE laser cleaning machine works in a non-contact and strictly controlled manner. You can control the heat to keep it from much higher temperature. Thus there will be no damage to the material surface.

CHUKE laser welding machine can create permanent welds with excellent efficiency and firm joints higher than the ordinary welding machines. Our customers can benefit from continuous welding, smooth seam and no follow-up polishing procedures.

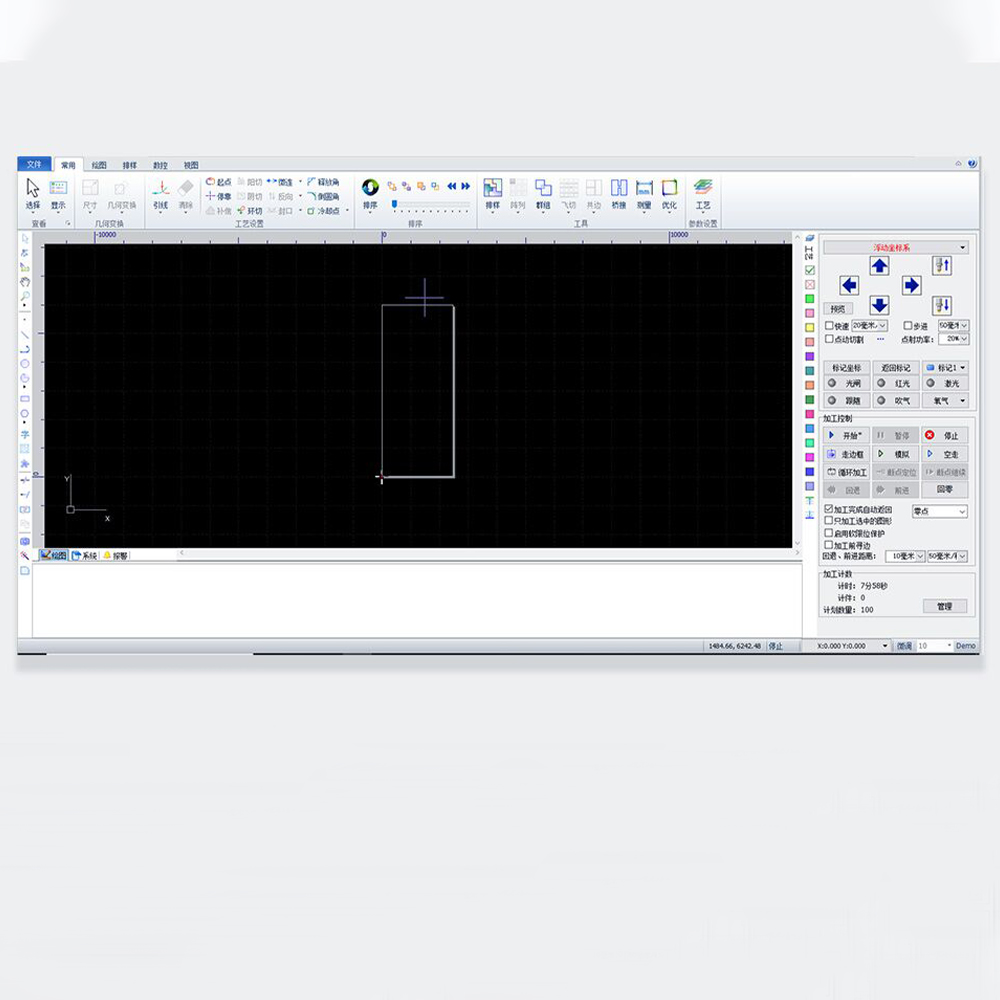

It has simple software of various parameter graphics, 12 different modes can be switched and selected quickly to facilitate production and debugging.

Specifications

|

Technical Data |

|

|

Name |

Laser Cleaning Machine |

|

Power |

100W/200W/300W/500W/1000W/1500W |

|

Average Power |

≥200W |

|

Screen Size |

7 inch(4.3/10 inch optional) |

|

Applicable Material |

Stainless Steel, Aluminum, Metal |

|

Laser Pulse Width Adjustment Function |

Supported |

|

Focus |

160mm(100-500mm optional) |

|

Cleaning Head Size |

367*70*75(L*W*H) |

|

Cleaning Head Weight |

Less than 0.95KGS |

|

Scanning Size |

100*100mm |

|

Maximum Scanning Line Speed |

20m/s max |

|

Galvanometer Type |

Digital Galvanometer |

|

Vibration Lens Material |

Monocrystalline Silicon |

|

Mirror Material |

Imported Quartz |

|

Field Lens Material |

Imported Quartz |

|

Cable Length |

6m(Customization is supported) |

|

Operate |

Handheld/Automated |

Advantages

With the advent of the era of Industry 4.0, some new intelligent industrial products have entered the market, and these new products must use surface treatment technology without exception, and it is necessary to transform the settled production capacity into advanced productivity. Laser cleaning technology is a new cleaning technology that has developed rapidly in the past ten years. It is gradually replacing the traditional surface treatment cleaning technology in many fields due to its many advantages. It can adapt to the cleaning of various surface contaminants, has minimal environmental pollution, and can achieve no damage to the substrate. At present, this method has become a supplement and extension of traditional cleaning methods, and has shown broad application prospects due to its many inherent advantages. Compared with the traditional cleaning process, laser cleaning technology has the following characteristics:

(1) It is a "dry" cleaning that does not require cleaning fluids or other chemical solutions, and its cleanliness is much higher than that of chemical cleaning processes;

(2) The scope of removing dirt and the range of applicable substrates is very wide;

(3) By adjusting the parameters of the laser process, the pollutants can be effectively removed without damaging the surface of the substrate, and the surface can be restored as new;

(4) Laser cleaning can easily realize automatic operation and reduce labor;

(5) Laser cleaning has high efficiency and saves time;

(6) The laser decontamination equipment can be used for a long time and the operating cost is low;

(7) Laser cleaning technology is a "green" cleaning process, and the eliminated waste is solid powder, small in size, easy to store, and basically does not pollute the environment.

Product detail drawing

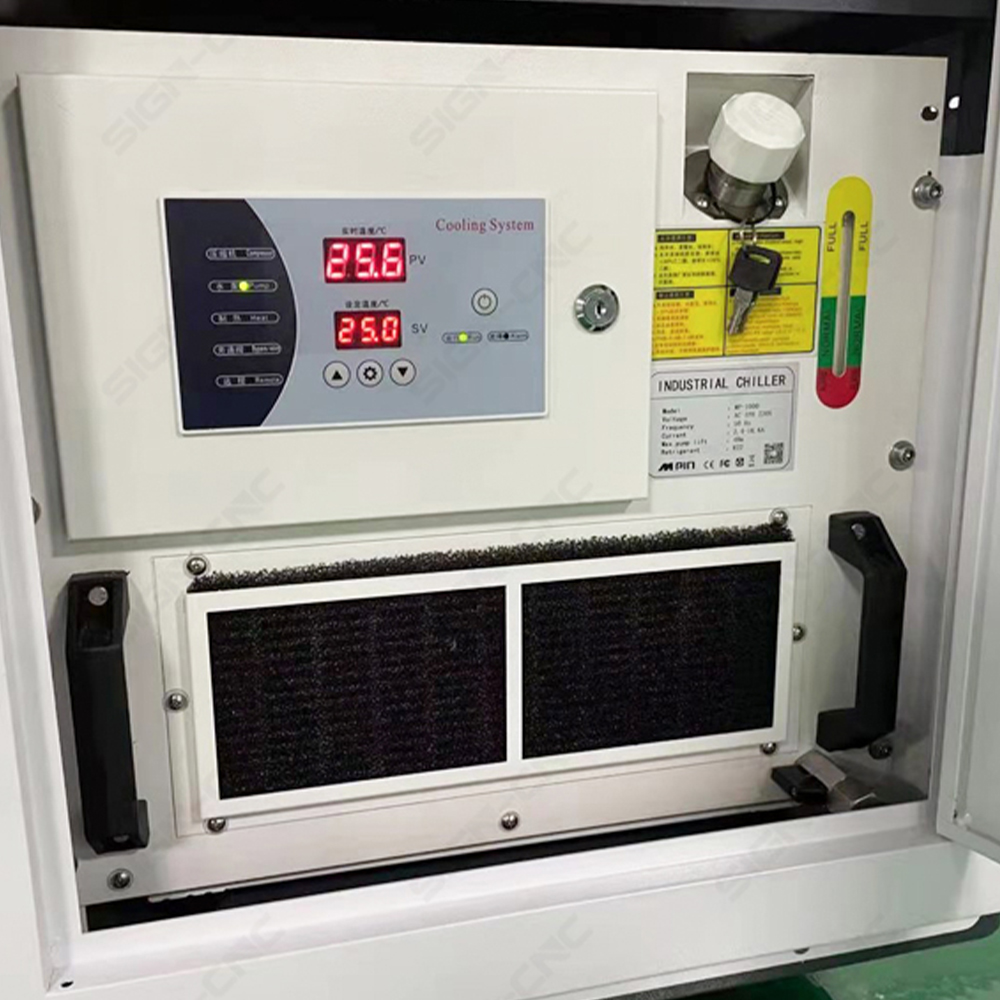

Water Cooler

Strong and stable water cooling system, ensure laser generator works perfectly

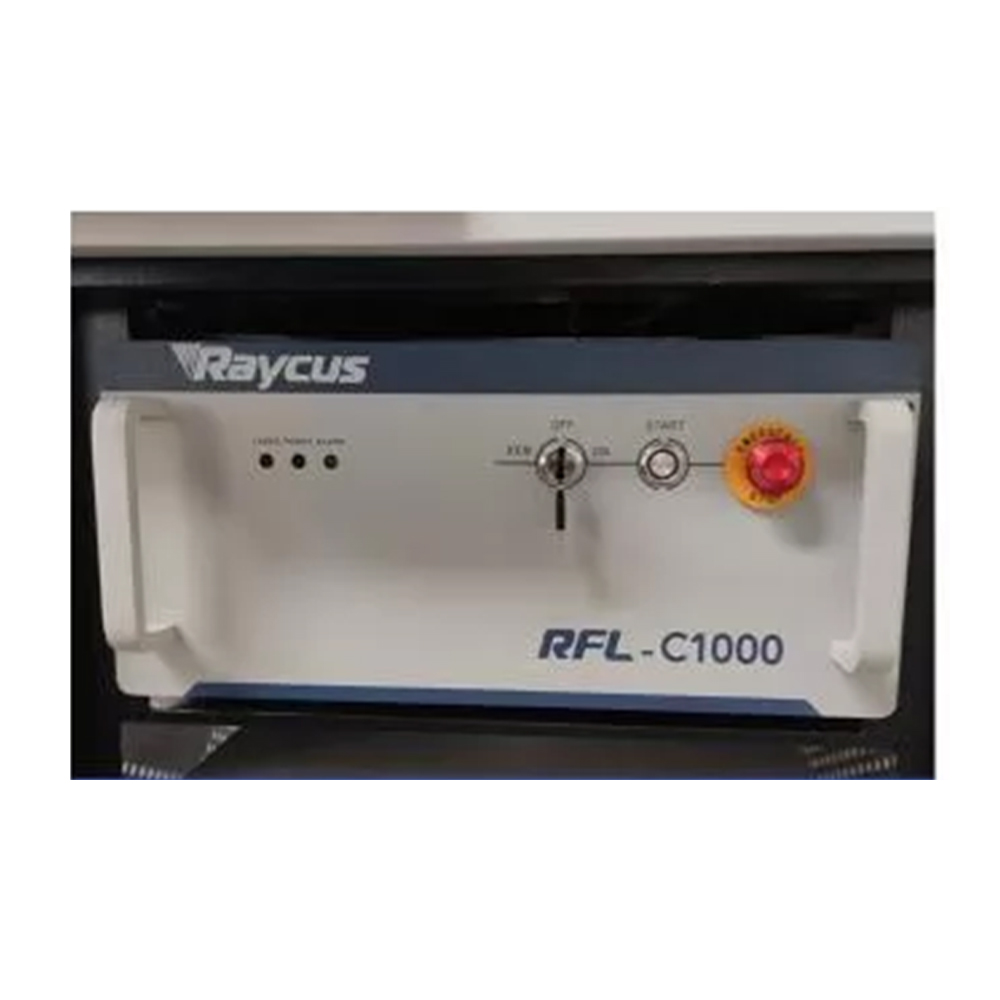

Raycus Fiber Source

Low power construction, easy to assemble. Most suitable laser source for industrial laser cleaning

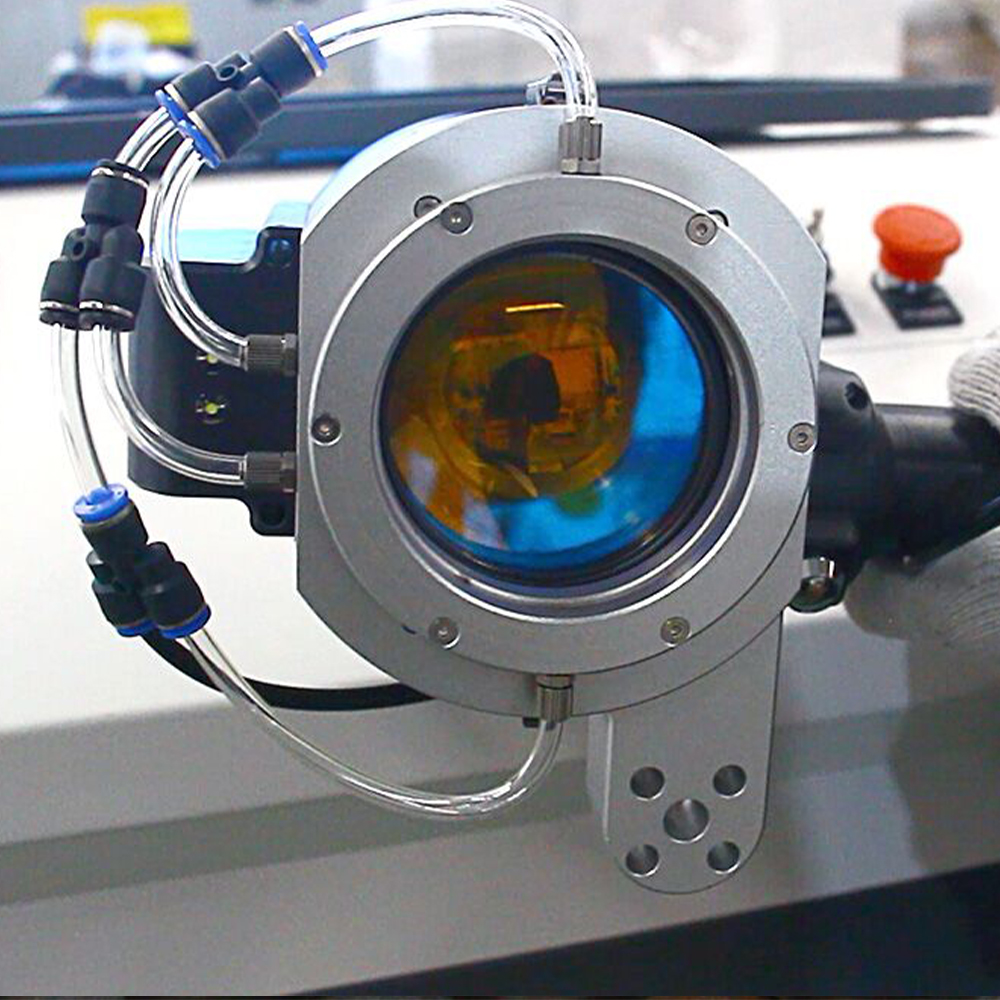

Cleaning Head

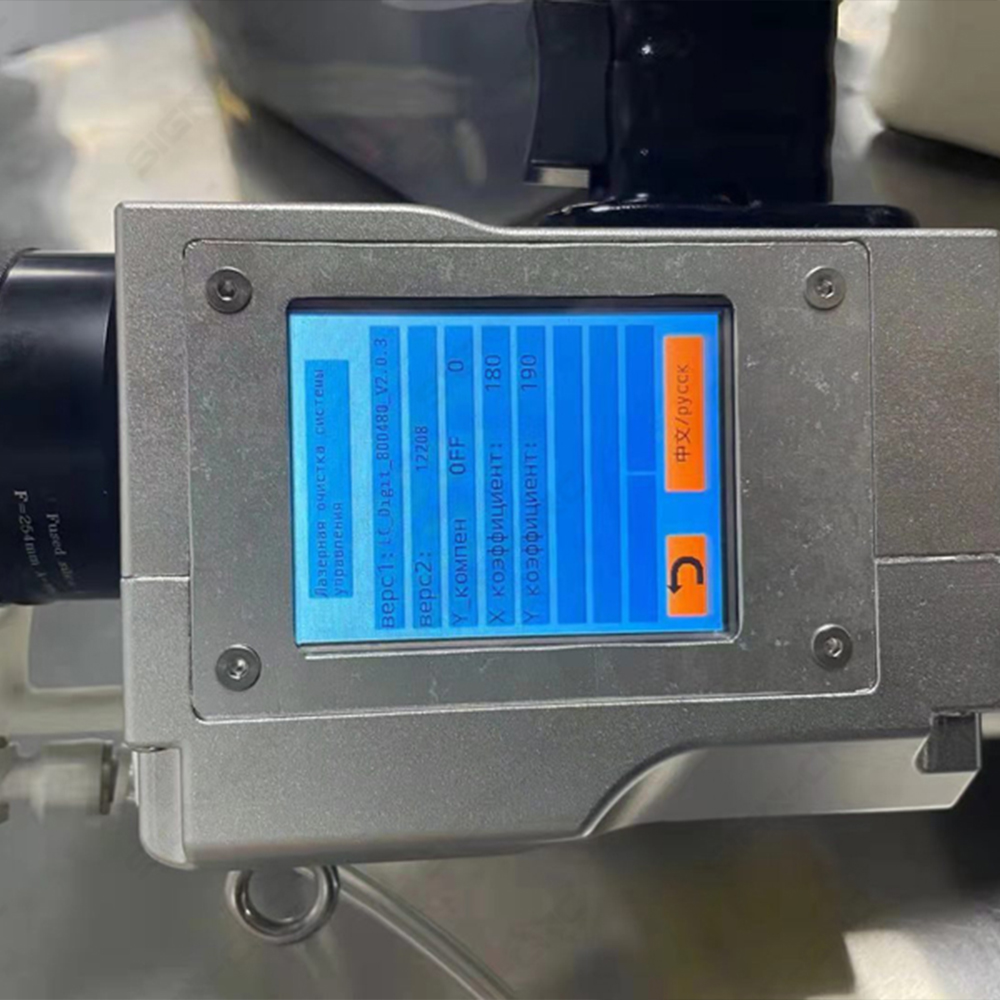

The newly designed cleaning head is comfortable to hold and equipped with touch display, which is convenient to adjust various parameters at any time

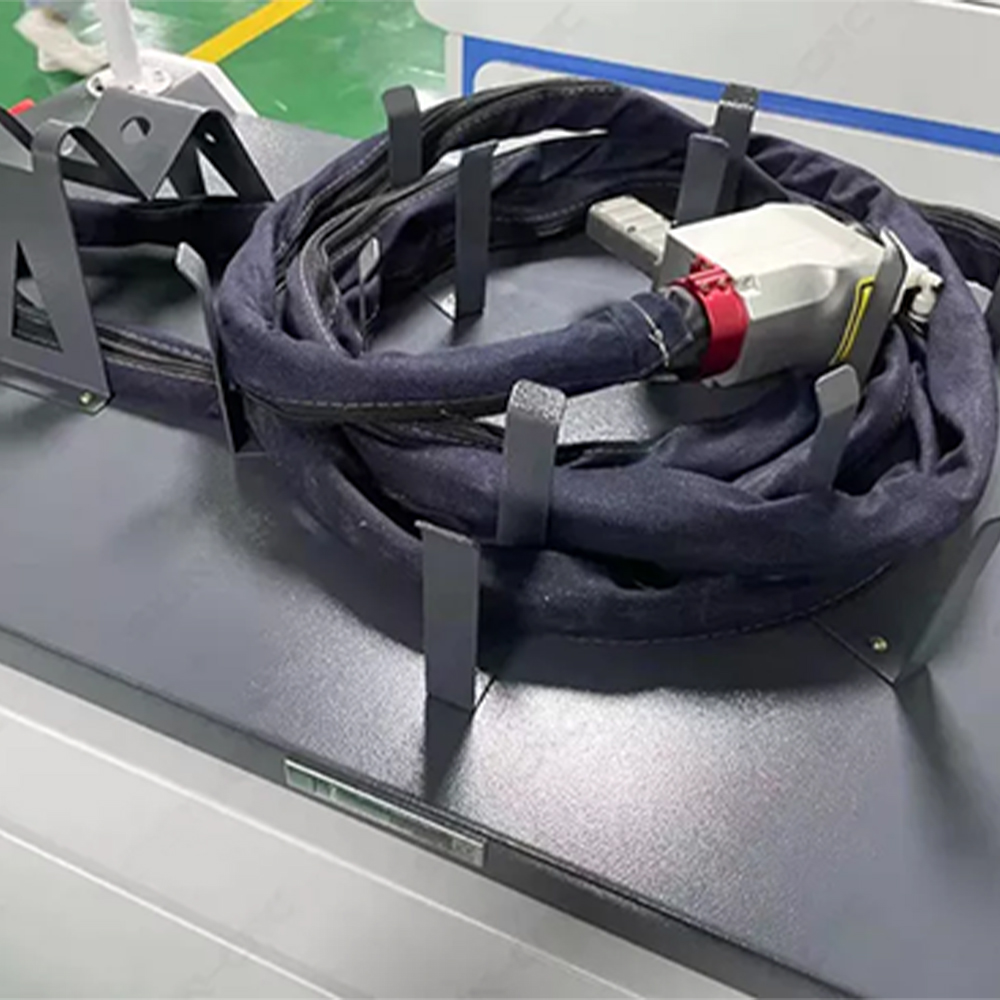

Cable

Standard 6m length for convenient work

CHUKE laser cleaning machine can be used for semiconductor components, microelectronic devices, memory templates and etc. Our machine has the absolute advantages of environment protection in the cleaning process high cleaning efficiency, high cleanliness, and no damage to the original material.