The vast majority of people are not sure what a laser cleaning machine is. They are not sure how good and advantageous it is for them to use it.

So in this guide CHUKE will give you all the details about laser cleaning machines.We'll tell you what it is and how you can use it to improve your work efficiency.

What is a laser cleaning machine?

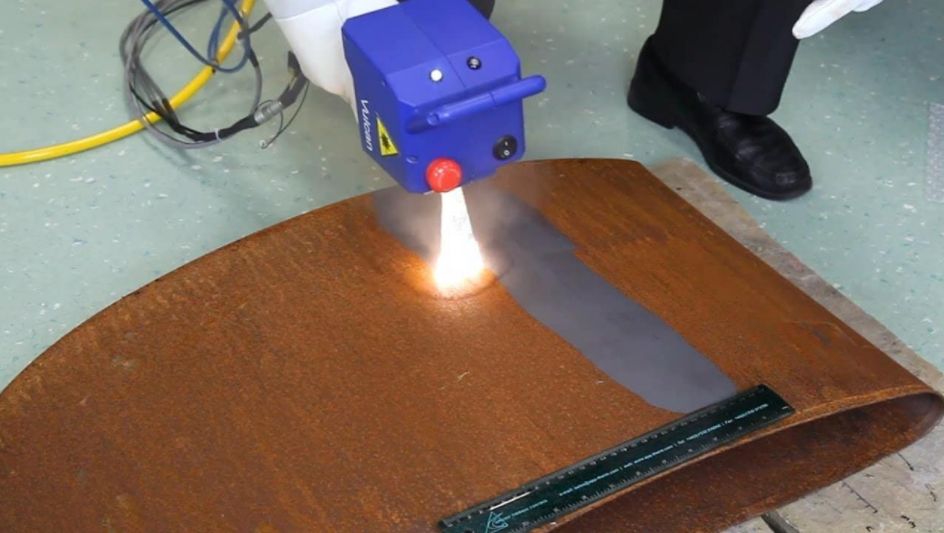

A laser cleaning machine is a device used to remove different types of oil, paint, dust from metal surfaces. It is considered as an eco-friendly process for removing pain, oxides, rust, and even other contaminants that can alter the state and condition of metals.

How does laser cleaning work?

It's easy to know the working principles, but how does a laser cleaning machine work?

The laser cleaning process works by sending multiple laser pulses across the surface. When the laser hits the substrate or metal surface, the contaminants either escape the surface or evaporate into a gas that keeps them away from the metal surface.

What can a laser cleaner remove?

Laser cleaners mainly remove rust or oxidation on metal surfaces.

In addition to rust, you can actually remove paint, oxides, and other substances that can contaminate the substrate.

Using thousands of laser pulses, pollutants will be greatly reduced, or better yet, eradicated. This process is called laser ablation for short. Laser ablation is a phenomenon that occurs when a laser beam is used to remove material or substrates.

When the laser beam hits the surface, the contamination layer evaporates or is removed along with the material plasma that may have deposited on it.

Where you can use the laser cleaning machine?

The most typical use of laser cleaners is to remove rust and oxidation from metal surfaces. Since there are many businesses and sectors that use metals, you will be able to use laser cleaners in many different industries.

Some of the most common commercial industries that use laser cleaners as followings:

Rail industry

Electronics industry

Shipbuilding industry

Automotive and automotive manufacturing

Steel and metal manufacturing

How to choose the best laser cleaning machine?

Here are some things you need to keep in mind before deciding to use a laser cleaning machine:

1)Laser cleaning machine specifications

This is the most important thing that you need to consider before you buy a laser cleaner.

While there are many different specifications that you can look at, there are some that stand out. Some of the best and most important technical parameters and specifications include

·Power

·Cooling method

·Power requirements

·Operating temperature

·Cleaning rate or cleaning efficiency

·Power consumption (min. or max.)

2)The substrate or material of your product

Obviously, laser cleaners are only effective on metal and steel substrates. Therefore, if you are well aware that the material or substrate you will be working with is not metal, then you are better off choosing a different cleaning machine for the job.

Otherwise, if you want to work on metallic substances and surfaces, a laser cleaner would be the best choice.

3)Contaminants or coatings you will remove

Please note that laser cleaners are effective in removing rust, oxidation, oil, grease, paint and other types of coatings or similar contaminants.

Using laser cleaners to remove highly chemically induced substances that may be dangerous and toxic to the environment or even to people nearby is not ideal

Sandblasting and Laser Cleaning

Many people don't realize that sandblasting is more than just a surface modification process. In fact, it is also one of the most effective ways to remove contaminants.

The complexity of comparing sandblasting and laser cleaning is that they both serve the same purpose, as you can use either of them to remove rust, grease, paint, oil, oxides and other contaminants.

The main difference between the two is that sandblasting has a minimal to moderate effect on the material, even if it is metal or steel. With laser cleaning, it has almost no effect.

Applications Sandblasting Laser cleaning

Heavy equipment/machinery Best Solution Not the best

Building or structural substrate components Best Solution Not the best

Aircraft and automobile exterior trim Not the best Best Solution

Complex hardware Not the best Best Solution

For over a decade, CHUKE have been the most trusted and sought-after laser cleaning manufacturing company in China. We employ the most skilled and experienced engineers and specialists who specialize in activities involving lasers.

Whether you need a handheld laser cleaner or an auxiliary laser cleaner, we've got you covered!

Post time: Sep-07-2022