High power UV lasers are widely used in wafer engraving, ceramic substrate cutting, silicon substrate drilling, flexible circuit board cutting and many other fields. With the continuous improvement of machining fineness and production efficiency, the beam quality, output power and stability of UV laser are required to be higher and higher. Maiman Laser has long been committed to the development and innovation of laser technology, especially in the aspect of high power UV laser has done a lot of innovative and pioneering work, developed high power, high beam quality, high stability UV laser, to meet the needs of laser microprocessing.

Maiman laser through the in-depth study of ultraviolet laser technology, summarized the influence of ultraviolet laser power increases, and long-term stability of the three factors, including the heating effect of the laser, three frequency doubling crystal damage, the disorder and long-term stability of the optical path, by solving the three aspects of technical bottlenecks, greatly improve the performance of ultraviolet laser, Thus the UV laser with high power, high beam quality and high stability can be realized.

High power UV, effectively solve power attenuation, and has superior beam quality and pulse stability, worry-free use

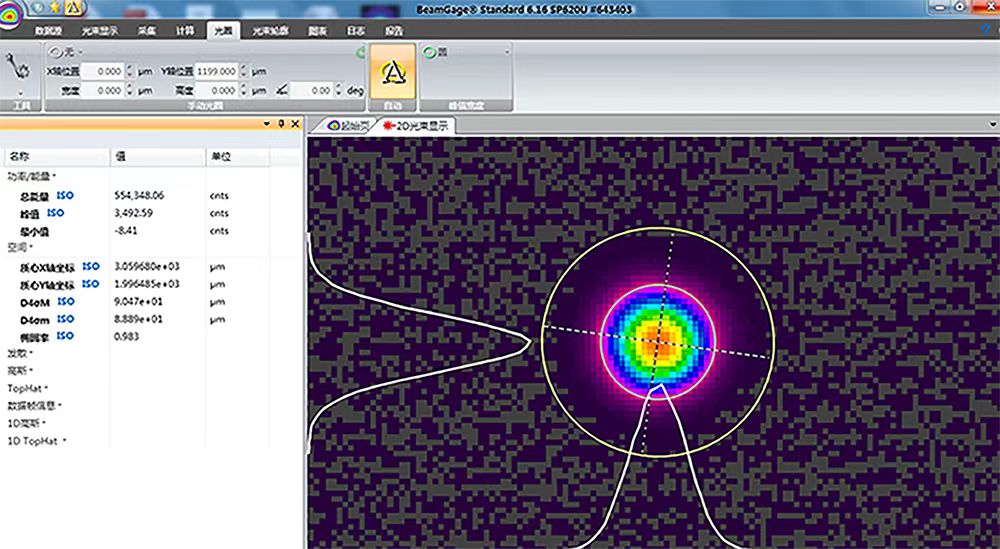

Spot contour diagram

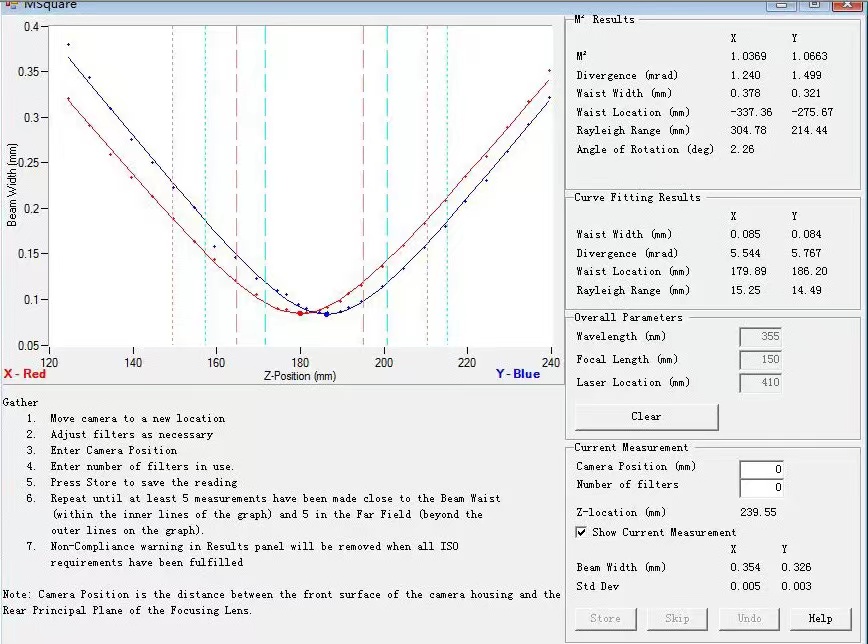

test pattern

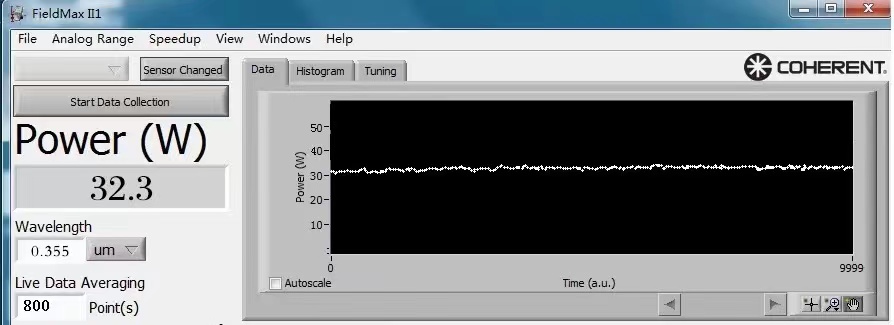

Stability of power

In the heating effect of the laser, maiman laser in the domestic leader in the pump wavelength laser diode resonance technology, through the different crystal parameters (doping concentration, temperature and length) and pump parameters optimization of power density and pattern matching (pu), effectively reduces the heat effect of laser, increased the mold oscillation light volume, The optical to optical conversion efficiency and beam quality of fundamental frequency light are improved, which provides a strong prerequisite for high power UV laser output.

In the aspect of anti-damage of the triple frequency crystal, Maiman laser reasonably designed the laser resonator to reduce the optical power density of the triple frequency crystal face and increase the upper limit of the output power of the UV laser while meeting the mode matching conditions. At the same time, the gas microcirculation system in the cavity and the non-metallization technology in the cavity are used to effectively control the volatiles produced in the cavity and improve the service life of the triple frequency crystal.

In terms of the disorders and long-term stability of the optical path, maiman laser adopts unique optical path compensation techniques and the optimization of cavity, reduce the misalignment sensitivity of optical resonator, improve the stability of optical path, in terms of the mechanical structure, shell by laser and optical mechanics analysis and calculation of mechanical parts, designed the mechanical structure, high stability of the optical And through the special processing method and heat treatment scheme to reduce the material shape variable, to ensure the long-term stability of the laser.

Maiman laser through the high-power ultraviolet laser multidimensional technical research, developed high power, high beam quality, high stability of 30W class, long life 355nm UV laser, the laser can meet the 7x24h high intensity environment and can maintain long-term stability, can be widely used in the field of laser micromachining.

Maiman laser with strong innovation ability, the market won a good reputation and extensive customer base, products range from the infrared to the ultraviolet, from continuous to a variety of pulse laser products.

CHUKE will learn from Maiman Company to make the best marking machine with high-quality lasers, so that the world will not have marking problems, and become a more professional marking machine factory.

Post time: Aug-29-2022