Laser Engraving, Cleaning, Welding and Marking Machines

Get a quote

Products

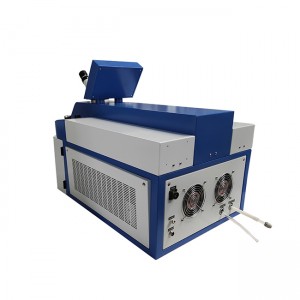

60W 100W 200W Jewelry Spot Laser Welder

The advantage of products

1.Cost effective: compressed air is not required,No consumables are required.

2.Efficient: Easy to start marking, from a single part to mass production,High speed marking (up to 5 characters per second). All kind of materials, from plastic to hardest steel.

3.Precise: Friendly software interface,easy to edit the marking content as you needs.

4.Simple: Multiple fixture options for optimal marking solutions.

5.Innovative: controller and marking head,designed more suit for handling and moving.

Parameter

| Product Name |

CHUKE Flange Marking Engraving Machine For Flanges |

| Marking speed | 2-5 characters(2x2mm)/s |

| Stroke Frequency | 300times/s |

| Marking depth | 0.01 to 2mm (Vary to the material) |

| Marking contents | Alphanumeric info, Data Matrix or dot matrix 2D codes, Shift codes, Barcode,Serial Number, Date, VIN Code, Time, Letter, Figure, Logo, Graphics and etc. |

| Stylus Pin Hardness | HRA92/HRA93 |

| Marking area | 80x40mm,130x30mm,140x80mm,200x100mm,300x150mm(customized support) |

| Dimensions | 320x420x740mm |

| Marking materials | below HRC60 metallic and nonmetallic materials ,above HRC60 need special stylus |

| Repeat accuracy | 0.02-0.04mm |

| Power | 300W |

| Work voltage | AC 110V 60HZ or AC220V 50HZ |

| Compressed Air( Pneumatic Air) | 0.2-0.6Mpa |

| Connection | 2 USB and RS-232 |

| Controller | a. 7"LCD touch screen controller b. windows 7.8 .XP system. |

| Power type | a.Pneumatic b.Electric |

| Marking directions | up, down, left, right, and the circular arc surface marking |

Product Accessories Display

● CHUKE Self-Developed Needle Core

CHUKE Machinery Factory developed it by itself It is processed by high-quality high-hardness alloy, and the coating is added with hard alloy, which has good wear resistance and strong impact force.

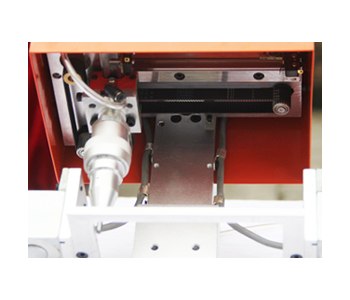

● High Precision Guide

Linear high precision guide , the equipment guide rail adopts linear guide rail, with high precision, low noise and high wear resistance, and the service life is greatly improved.

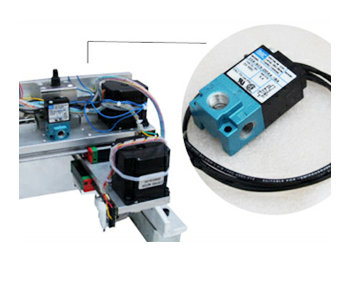

● Brand Solenoid Valve

Japanese solenoid valve or MAC solenoid valve , the equipment solenoid valve adopts Japanese solenoid valve or MAC solenoid valve, which has high frequency, fast speed, strong environmental tolerance and long service life.

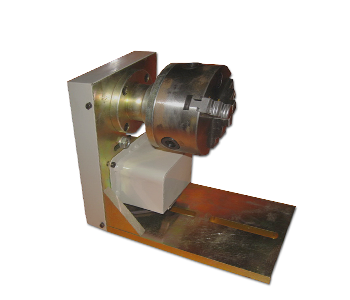

● Rotary Fixture

custom tooling plane, arc, and circumference marks can be switched at will, and the tooling of the parts can be customized for free.

Marking Samples